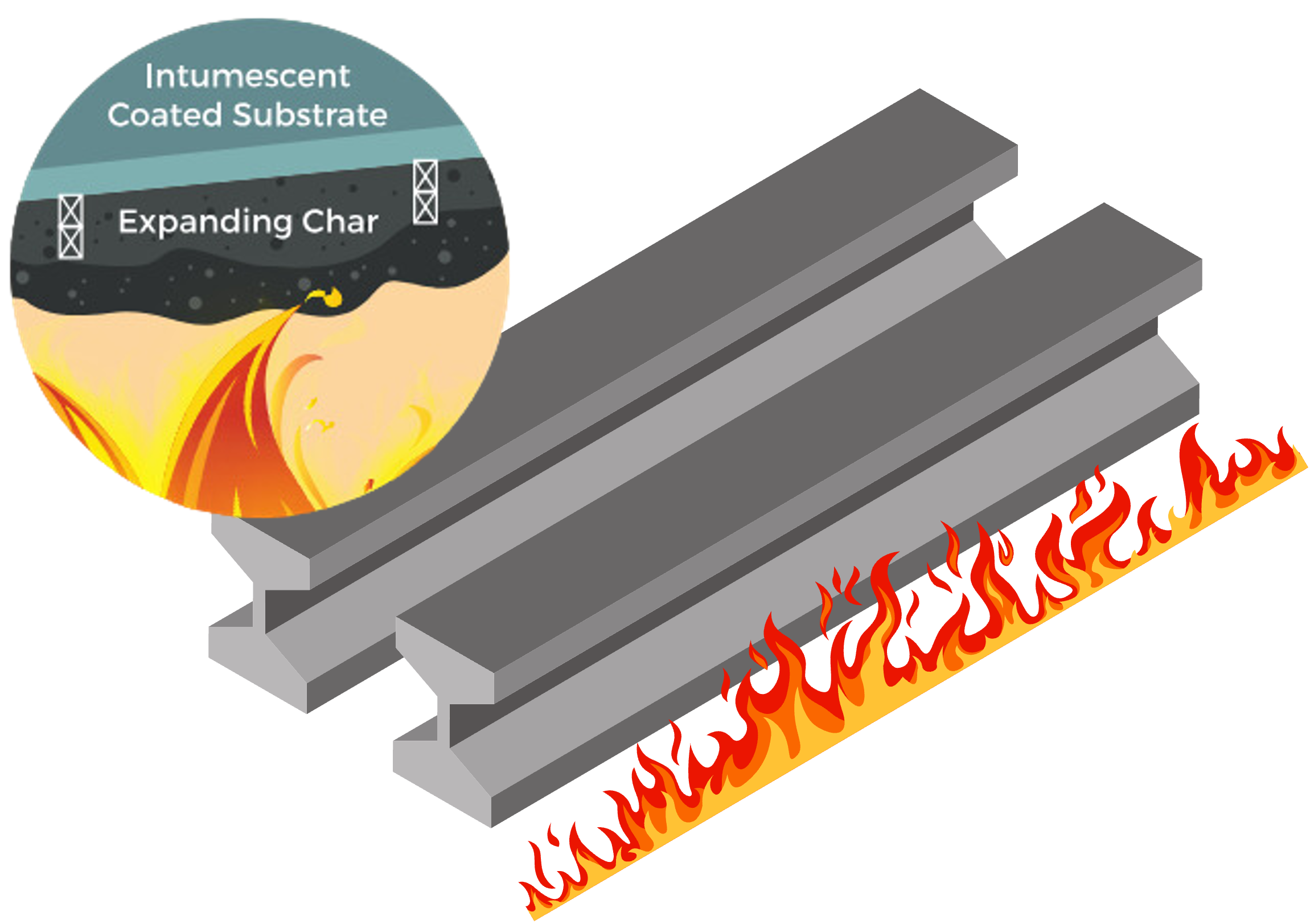

Fire Resistant Intumescent

BLAZTA FD is an intumescent coating that creates a fire retardant and fire resistant barrierfor stell constructions. Design to protect for up to 120 minutes on a wide range of I section beams, columns and hollows.

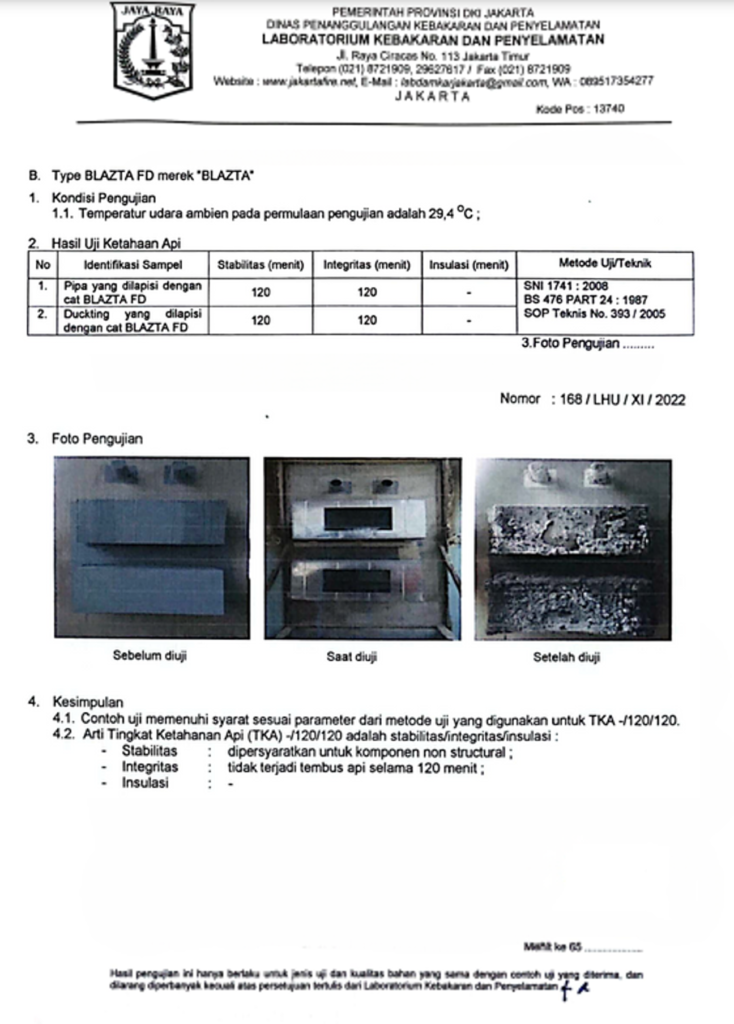

Tests are carried out based on the following standards:

- SNI 1741 : 2008

- BS 476: Part 24: 1987

Application Method

Brush & Paint Roller

Advantages – low cost and often the most suitable way to paint complex objects. Works well for rough surfaces.

- Use a good quality brush / paint roller that’s as large as possible for the job.

- Don’t use a new brush / paint roller for the final coat, the tend to shed bristles.

- Use a criss cross motion, brush / paint roller from side to side and then up and down.

- Continue until the paint is evenly distributed over the area.

- Angle the brush at 45 °C angle to minimize brush marks.

- During application the paint will start to dry on the brush / paint roller. It is recommended that you clean the brush / paint roller every 30 minutes to keep good painting consistency.

Spray equipment

Advantages – quickest application method, cuts down on labor. Delivers smooth, uniform coats.

- Use 3.8 liters per minute electric airless (minimum) to provide an operating pressure of

3000 psi (210 kg/cm²).

Intumescent coating – mixing

Mixing : power stirring is required to thoroughly mix the intumescent coating. The intumescent coating should be a uniform, smooth and creamy consistency. Hand held mixers are recommended to be used with a slotted drywall paddle 2 – 3 minutes of mixing is recommended. Use ½ inch electric or air driven drill with a slotted paddle mixer (300 rpm under load)

Job-site downtime

Job-side downtime may occur when other trades are in the building, or between applapplication coats. If this occurs, immerse the tip of the gun in water and cover the open product pail that is being applied. For extended downtime, it may be necessary to run water through the pump and hose. If a skin occurs on the top of the intumescent coating in the bucket, remove paint skin. Do not mix or try to spray. This will cause tip clogs and will result in a undesirable finish.

Applying multiple coats of intumescent paint

Multiple coats of intumescent paint are usually necessary to achieve the required Dry Film Thickness (DFT). The thickness per coat is based on the applicator’s experience, application equipment, and environmental conditions.

Example : an experienced applicator may be able to achieve the smooth finish by applying 0.2 mm wet while the inexperienced applicator may only be able to achieve 0.1 mm.

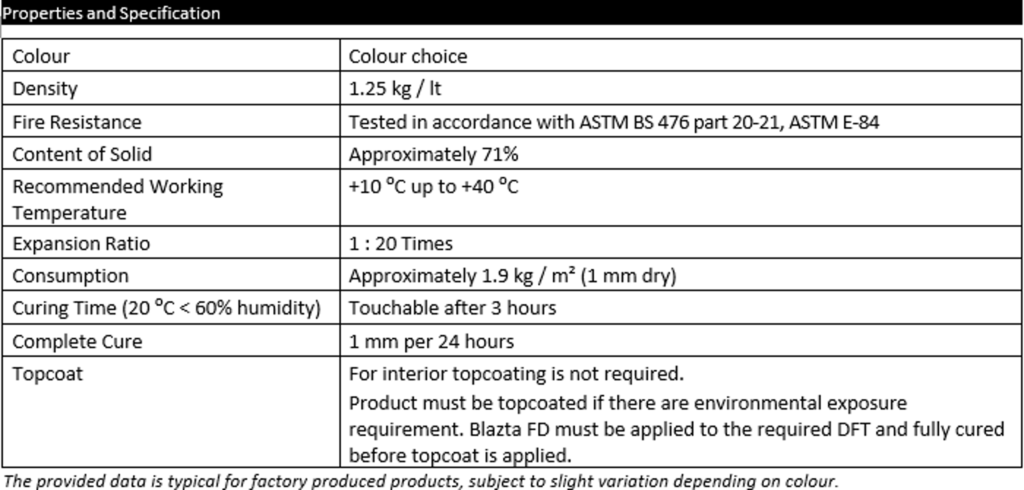

Application thickness

Required paint thickness is given in mm Wet Film Thickness (WFT) or Dry Film Thickness (DFT) and is dependent upon the substrate it is applied to, and the desired fire rating.

WFT is measured during application process. DFT is measured after the coating has cured.

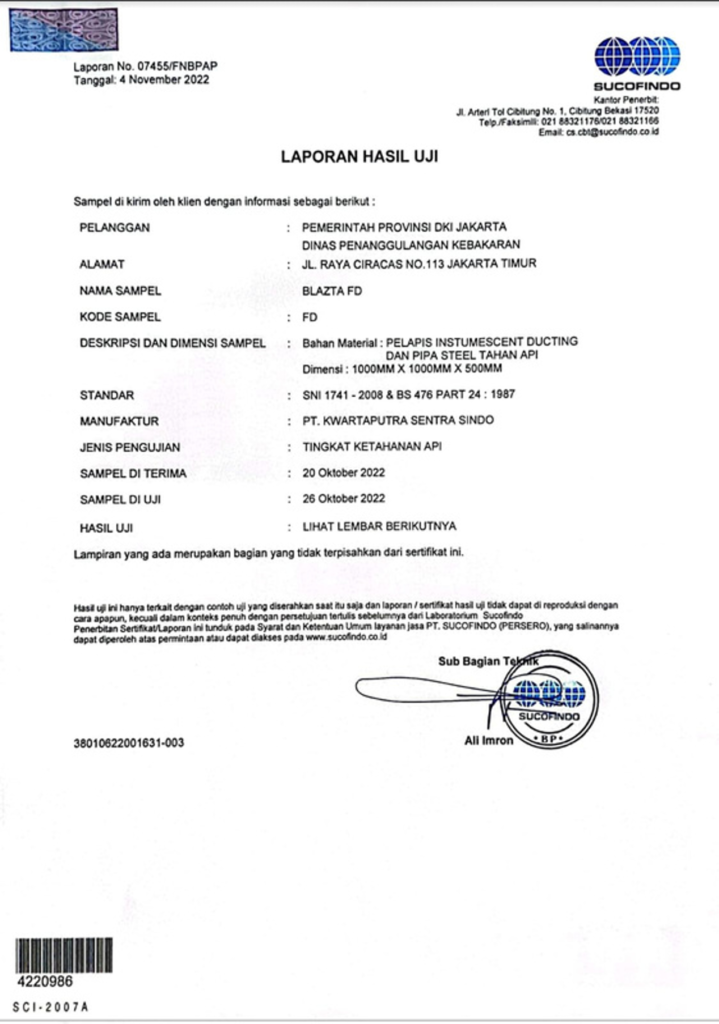

Certificate